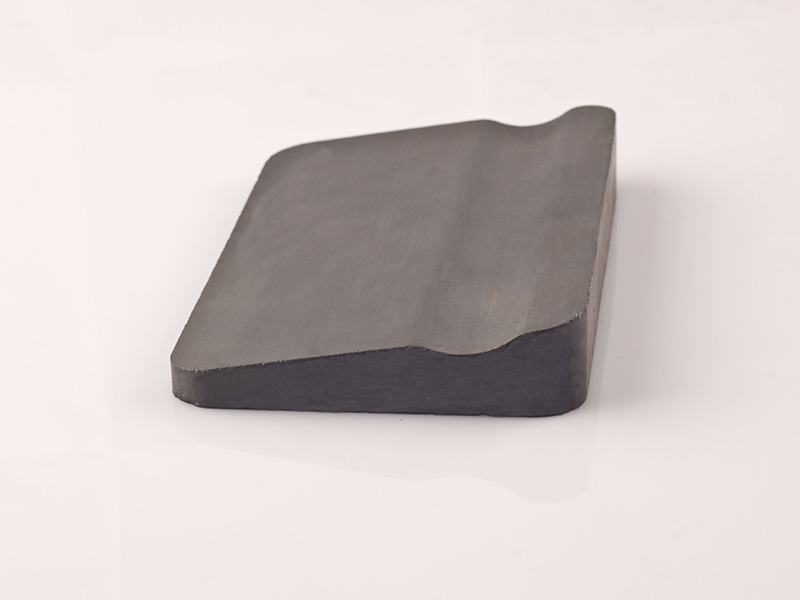

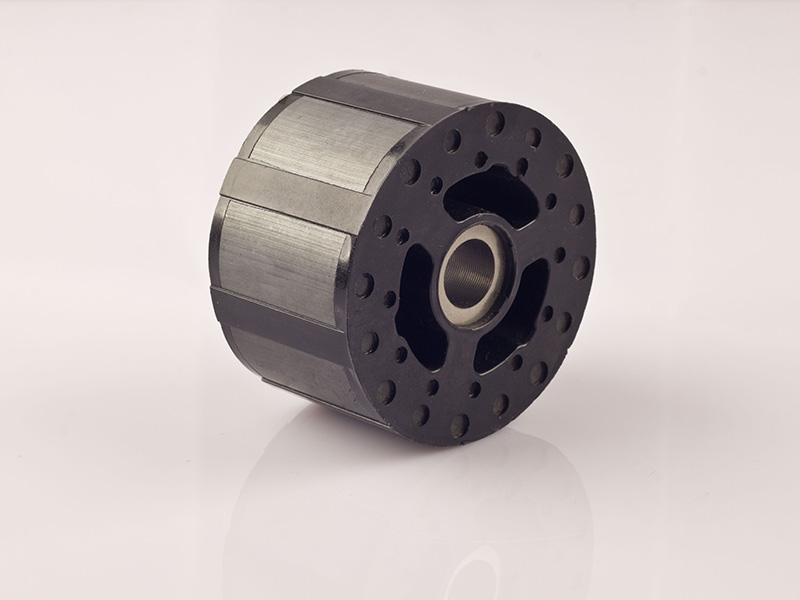

The main raw material of ferrite magnets is SrO and Fe₂O₃. Ferrite magnets have the feature of high cost-performance, wide application, good corrosion resistance which does not require surface treatment. Our company can produce a variety of high-performance magnets in different shapes such as arcs, rings, discs, blocks and other special shapes. With our specific formula, we can produce ultra-high-performance ferrite -- lanthanum cobalt magnet